The plan is to start with a half-scale clay model that will be cast in plaster. The half-scale plaster will then be enlarged (using the 3-D pantograph) into a full-size clay. The full-size clay will then cast in a permanent plaster model that can be transferred point-by-point into stone using the traditional pointing machine. Here we do the first two of those steps–making the miniature model.

Sculptors of the Nineteenth and early Twentieth Century routinely worked this way. A successful sculptor’s time was too valuable to waste on work that could be offloaded to skilled assistants or tradespeople. The common process in the late Nineteenth and early Twentieth Centuries was for the nominal artist to work in miniature–usually between 1:5 and 1:2 scale–and hand off the rest of the of the work to specialists, either in-house assistants or contractors. Virtually all of the well known sculpture of the period was done this way. If a piece was not site-specific, the full size plaster would typically be exhibited and the decision as to medium was often left to the purchaser. (Many pieces were in fact produced in both bronze and marble.)

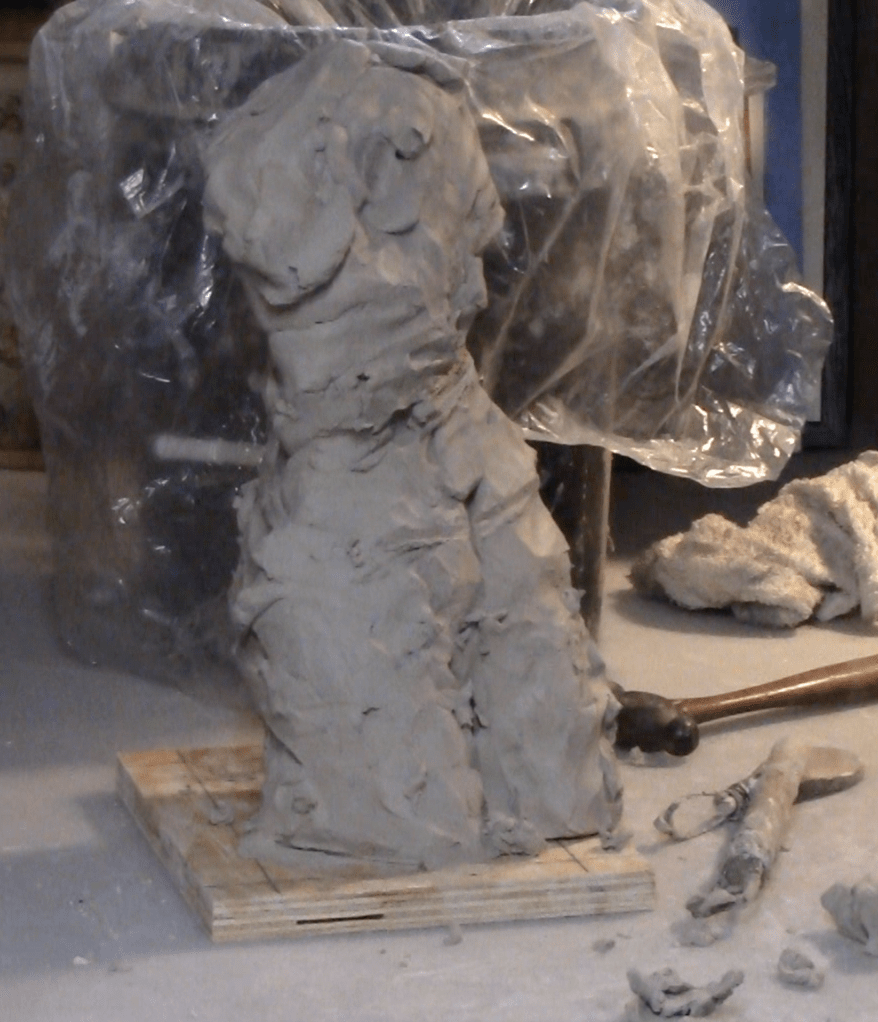

Really early version.

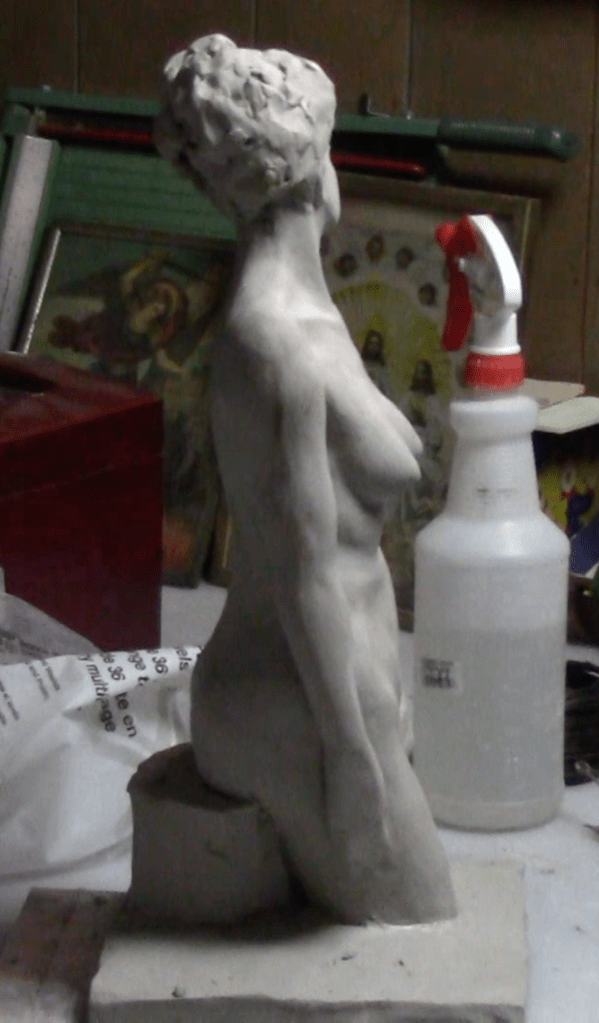

Version one. I liked it, but it wasn’t quite what I needed.

Version two. The wall is approximately where the stone will be.

Walls for the one-sided mold.

Clay walls to hold the plaster.

It’s fun to chip off the plaster waste mold!

The romantic image of the artist wresting the sculpture from the stone was never true, least of all in glory days of late Neoclassicism and the Beaux Arts. For successful sculptors it was more like handing off blueprints to a builder.

Exactly how far you take the enlarging process is a matter of circumstance and taste. I’m doing the whole thing myself, so there’s no advantage in down-to-the-millimeter precision in the enlargement. If you’re handing work off to an assistant or executing a piece from someone else’s plaster original, precise enlargement is more important.

I ended up with two versions of this. You can see part of the two piece mold for the first version on the back of the table. I’ll have to pour that one day.